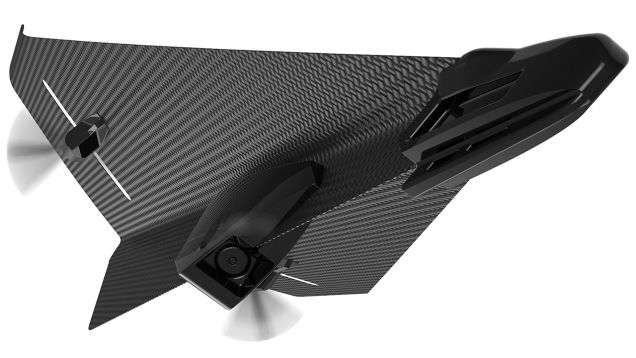

First FAA-Approved 3D-Printed Components for 787 being used by Boeing

The Boeing Company is expecting to cut off 2-3 million U.S dollars from its each manufacturing cost for Dream-liner 787 by the year 2018 and it is due to 3D-printed titanium. The company has now teamed up with Norwegian company “Norsk Titanium” in order to manufacture the first printed mechanical titanium parts for the plane. Reuters pointed out that the General Electric Company has already printed fuel nozzles for engines of the aircraft. It has been considered that a company is using 3D-printed elements for engine parts for the first time. These components will bear the stress of an airframe during a flight. The Boeing Company is currently turning to 3D printing only for 787 due to it needs extra amount of metal compared to its other models.

The conventionally manufactured titanium alloy will be more expensive since the company is manufacturing 144 Dream-liners per year. The partnership of Aerospace Corporation has been considered an unambiguous recommendation for printed metal parts in the aviation industry. It will be a proof that companies have shown their trust in the manufacturing process and its advanced materials. The Boeing Company worked with “Norsk” from the beginning of 2016 to February 2017 in order to pass the inflexible testing program for the components from the Federal Aviation Administration (FAA). The partners were expecting to get additional FAA approval last year for the properties of material and manufacturing process. It would allow the Norwegian Company in manufacturing more 3D-printed titanium parts without getting further approval.