Readymix London – Why Need to Choose Readymix?

When one is looking for ready mixed concrete in London, it is best to research thoroughly before finalizing. When looking for a concrete supplier who can provide a high-quality mix that is both affordable and dependable, it is easy to find a good supplier with research.

The Benefits of Ready-Mix Concrete

When there is a need to make repairs or build structures, one may need ready mix concrete. One can easily locate a local supplier through the yellow pages or Google. Call the local ready-mix supplier to discuss the plans. Let the company know what the project entails, and they will determine how much concrete is needed. Be sure to schedule the delivery well in advance to ensure that the concrete arrives on time. By doing so, one will save time and money.

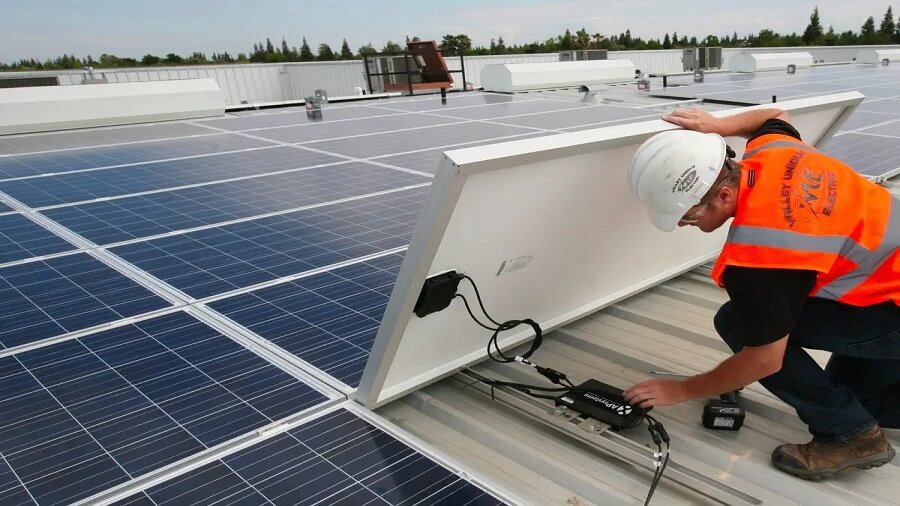

Readymix London trucks are huge and create additional road traffic. The trucks may be blocking other traffic, and the access roads they use should be able to support their weight and the weight of the load. Using a mini mix company, which uses a four-m3 mixer, can reduce the traffic impact on local roads. Depending on the size of the project, mini-mix companies may be better suited for smaller projects. The main difference between mini-mix companies and large-scale ready-mix facilities is the size of the mixing truck.

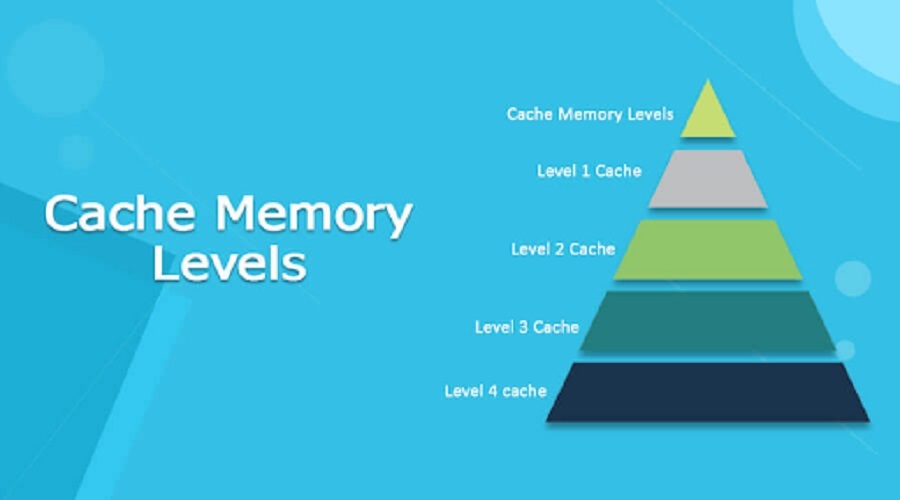

Concrete is usually divided into different classes based on the size and consistency of its constituent parts. Consistency is the measurement of how easily and evenly fresh concrete can be mixed without losing its homogeneity. This is important when mixing concrete because it should be homogeneous during transport and placement. The workability can be protected during forming, pouring, and finishing processes. Adding additives increases strength and reduces curing time. These factors contribute to the overall durability and strength of the concrete.

Readymix London concrete requires minimal transportation time and is generally higher in quality, as the variation between batches is low in a plant environment. The most appropriate type of concrete will depend on the location of the project, but site-mixing is more cost-effective for smaller construction projects. Once a concrete mixture is prepared, the contractor can begin construction. Once the concrete is set, the job site will be completed sooner than ever. There is no reason not to use it!

Another benefit of ready-mix concrete is that it is easily molded into any shape and is inexpensive. Ready-mix concrete is also more aesthetically pleasing than brick. Compared to brick, it is cheaper, easier to transport, and gives a uniform look. Bricks require time to transport and require additional labour to lay them. And bricks can cause segregation. A large number of consumers may not be familiar with the benefits of ready-mix concrete.

This product is manufactured in a factory or batching facility according to a set recipe and then delivered to construction sites by truck mounted mixers. It is a convenient alternative to wheelbarrow loads of concrete. And ready-mix concrete can also be customized for any specialty construction. Founded in the 1930s, the industry of ready-mix concrete has continued to grow. It accounts for nearly three-quarters of the concrete market.

The most important component of ready mix concrete is cement. It provides the structure with its strength and resistance. Water is a crucial fluid, setting off a chemical reaction between the cement and aggregates. The remaining material is composed of aggregates, which typically make up about 60 per cent of the mix volume. Aggregates come from quarries or aggregate banks. Aside from the ingredients in the mix, ready-mix concrete can also include liquid or solid additives. They may increase durability and shorten the setting time of the concrete.