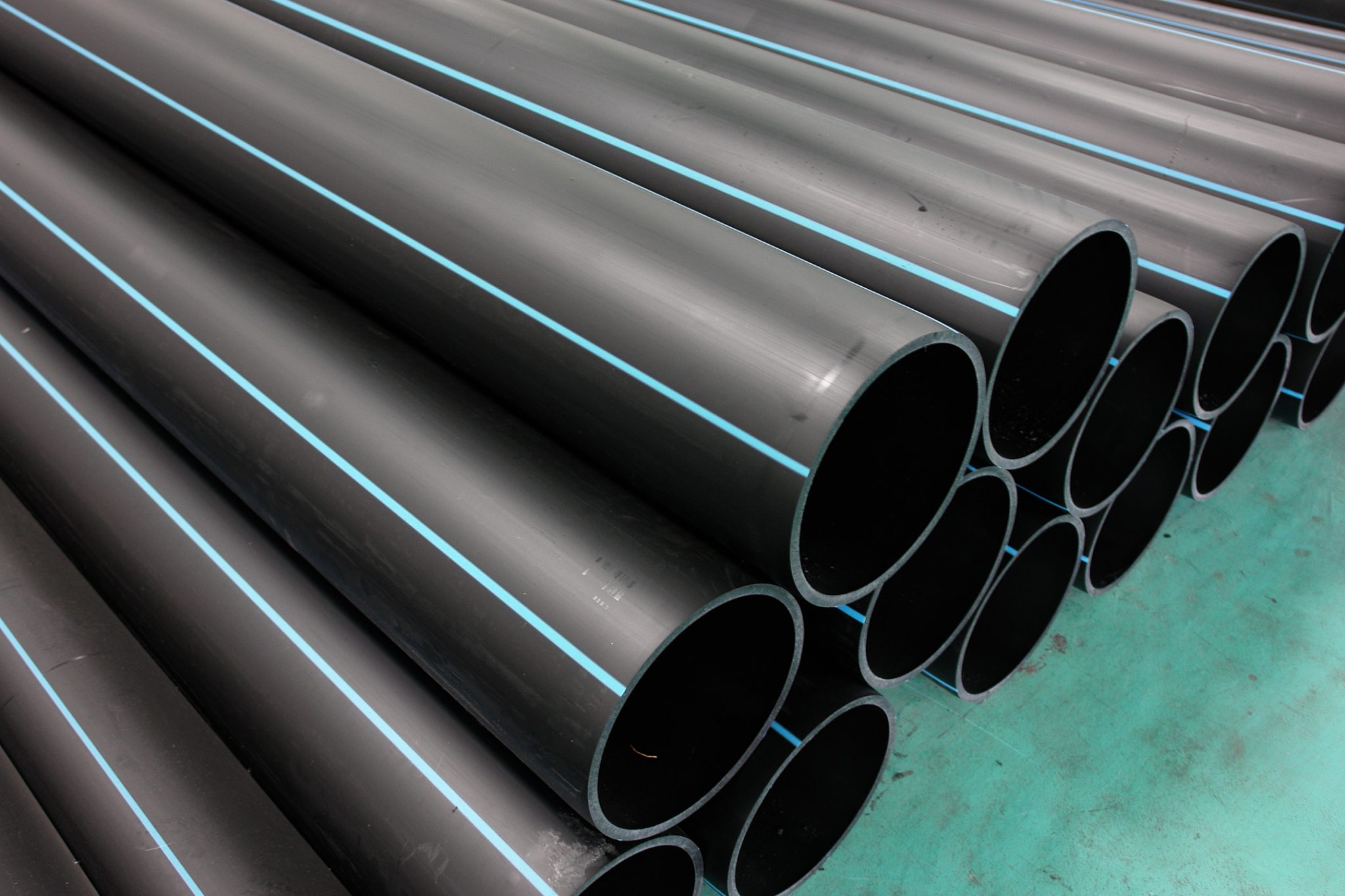

Reasons Why HDPE Pipes are More Preferable than Other Pipes

HDPE Pipes – Taking on the difficulties of the twenty-first century!

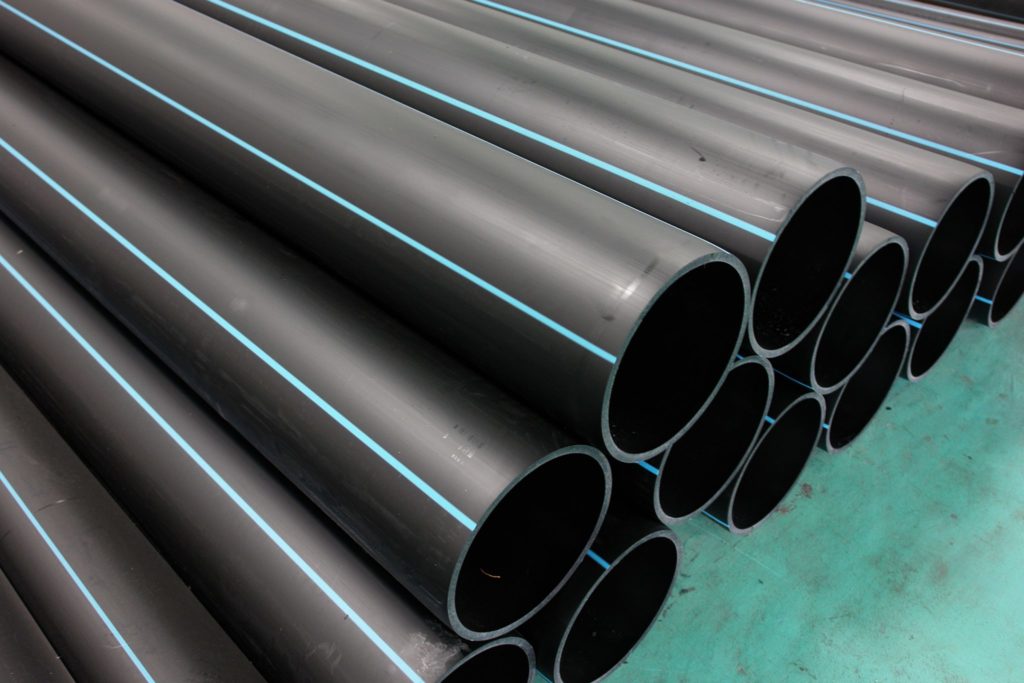

Polyethene pipe is a low-cost solution for many piping challenges in municipal, landfill, duct, marine, mining, industrial, and agricultural applications. It has been tested and confirmed to be effective in above-ground, surface, buried, slip lined, floating, and sub-surface maritime applications.

HDPE pipes transport potable water, hazardous wastes, slurries, chemicals, wastewater, and compressed gases. Polyethene pipe has a long and illustrious service history in the mining, gas, oil, and other sectors. Compared to all other pressure pipe materials used for urban gas distribution, it has the lowest maintenance frequency per mile of line each year.

When it comes to fittings, PVC Pipes are a strong, exceedingly robust, and exceptionally durable material. High-density polyethene pipe will fulfil all your needs, whether you want extended service, flexibility, easy installation, chemical resistance, or a variety of other properties.

HDPE Pipes Saves Both Time and Money

Reduced Life Cycle Costs

- Corrosion resistance. Similar to PVC pipes, they will not rust, decay, or corrode.

- Keep leaks to a minimum. Heat-fused joints produce a unified, monolithic system. The fusion joint is more potent than the pipe.

- Ensures that optimal flow rates are maintained. It is resistant to scale and biological build-up and does not tuberculate.

- Excellent water hammer properties. Its construction resists surge situations.

- Allowance for high strain. It eliminates breakage due to frozen pipes.

- It reduces repair frequency results in additional cost savings.

- Water losses and groundwater nuisance treatment. Expenditures associated with typical pipe systems are minimised with HDPE since there is no exfiltration or infiltration.

Reduced Installation Expenditures

- Trenchless technology’s preferred material. Directional dull, ploughing, river crossings, pipe bursting, and slip lining are all applications.

- Because of the flexibility of the pipe, fewer fittings are required. With a bending radius of 20 to 25 times, this pipe’s outer diameter is permissible.

- Handling and installation equipment is less heavy than other metallic materials.

- It removes the necessity for thrust blocking like PVC Pipes. Joints that have been heating fused are entirely restricted.

- Lightweight and more extraordinary lengths allow for substantial labour and equipment savings.

Features Making HDPE Pipes an Ultimate Choice

The Material is Free from Leakage

Heat fusion is commonly used to link polyethene pipes. Butt, socket, sidewall fusion, and electrofusion work together to form a junction as robust as the pipe itself and almost leak-free. This HDPE’s unique connecting technology results in considerable cost savings compared to other materials.

Flow Characteristics of This Pipe Are Excellent

Polyethene is smoother than steel, cast iron, ductile iron, or concrete. Therefore, a little PVC Pipes may carry the same volumetric flow rate at the same pressure. At high flow, it has reduced drag and a decreased inclination for turbulence. Its solid chemical resistance and “non-stick” surface work together to virtually avoid scaling and pitting while preserving the pipe’s good hydraulic qualities throughout its service life.

Toughness and Ductility is a Plus Point

Polyethene pipe fittings are robust, durable, and resistant to damage from external loads, vibrations, and pressure spikes such as water hammers. Polyethene pipe is resistant to handling and bending even in cold temperatures.

Available in Size Ranges From 12 To 63 Inches

Polyethene pipe is available in a variety of diameters and wall thicknesses, as well as flanges, elbows, tees, wyes, and valves, allowing for a complete system solution. HDPE pipes come in Iron Pipe Size (IPS), Ductile Pipe Size (DIPS), and metric sizes. Members of the Plastic Pipe Institute can supply lines, fittings, and other accessories.

HDPE Pipes are Flexible and Have Lightweight

Polyethene pipe is available in both straight lengths and coils. It is lightweight and does not require large lifting equipment for installation since it results from rough materials, one-eighth the density of steel. It eliminates the need for fittings, works well on changing soils, and is effective in earthquake-prone places. HDPE is resistant to freezing and allows for bending without the need for an excessive number of fittings. Because HDPE is not brittle, it may be laid in continuous lengths with bends over rough terrain without the need for extra welds or couplings.

The Sum Up!

HDPE (High-Density Polyethylene) pipe is suitable for many applications, including municipal, industrial, energy, geothermal, landfill, etc. HDPE pipe is robust, long-lasting, flexible, and lightweight. Also, it has a 0% leak rate when fused because the fusion process generates a monolithic HDPE system. Moreover, HDPE pipe is an ecologically friendly solution because it is non-toxic, corrosion-resistant has a long design life and is perfect for trenchless installation methods due to its flexibility.